Empower Manufacturing with Adaptive Solutions

Key areas of impact

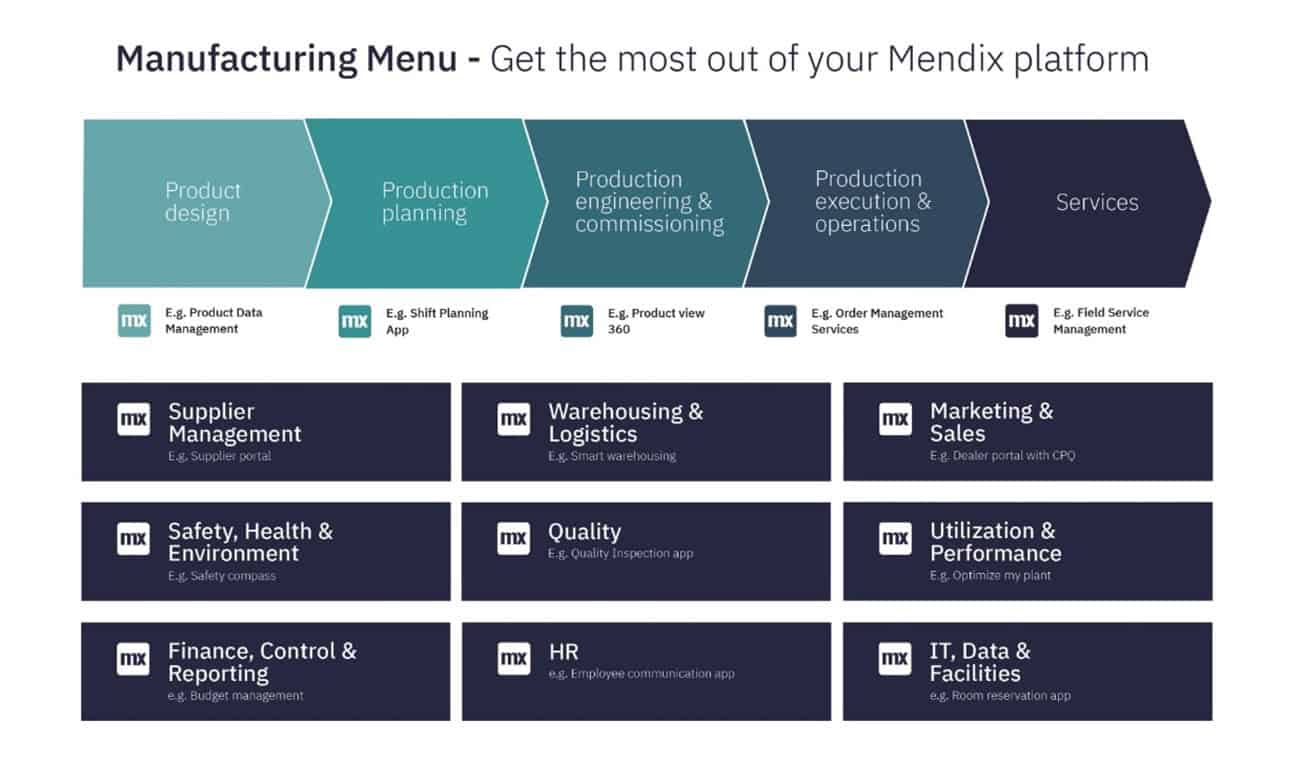

In the previous articles in this series, we discussed the components of the Manufacturing Menu and their impacts on different areas of manufacturing operations. In this article we’ll focus on three additional areas: Quality Management and Compliance, Safety and Health, and Resource Optimization.

These areas are crucial for manufacturers who aim to:

- Maintain high standards

- Ensure workplace safety

- Optimize resource use

By leveraging the Manufacturing Menu, manufacturers can create tailored, scalable solutions that promote innovation and sustain a competitive edge in an increasingly complex industry.

Quality management and compliance: Ensuring excellence and building trust

To dive into how the Manufacturing Menu can transform operations, let’s start with Quality Management and Compliance. Maintaining high standards of quality and ensuring compliance are essential for success in manufacturing. The Manufacturing Menu provides customizable solutions that allow businesses to integrate strict quality controls into their processes.

For example, VDL Nedcar, a leading automotive manufacturer, replaced their labor-intensive paper-based system with a digital solution powered by the Manufacturing Menu. By implementing a native mobile app integrated with QR code technology, they gained 100% visibility into their quality metrics. This enabled them to streamline operations and optimize production.

Similarly, BKD, a respected certification organization, developed an offline app using Mendix React Native technology to improve the accuracy and efficiency of their inspections. With this app, BKD was able to:

- Consolidate workflows

- Receive real-time guidance

- Improve inspection outcomes

By using solutions like these, manufacturers can prevent costly issues and drive continuous improvement, turning quality management into a strategic advantage.

Safety and health: Leveraging low-code for a safer workplace

Ensuring the safety and health of employees is vital in manufacturing. Still, many companies use outdated manual processes that can reduce effectiveness. The Manufacturing Menu offers advanced tools to embed a robust safety compass—comprising procedures, guidelines, and technology—directly into daily operations.

VDL Nedcar significantly improved their security checks by adopting Emixa’s Security Round App . This app uses Near Field Communication technology to automate and verify rounds, enhancing reliability and efficiency.

VDL Nedcar also replaced their paper-based emergency procedures with the Evacuation App from the Manufacturing Menu. This app provides real-time updates on employee locations during evacuations, ensuring faster and more accurate headcounts.

By integrating these tools into their safety compass, manufacturers can shift from manual processes to a more proactive, technology-driven approach. This helps create a safer and more responsive work environment.

Resource optimization: Maximizing efficiency and performance

Manufacturing operations involve a complex system of machines, people, and processes. These must all work in harmony to avoid issues like:

- Machines idling due to missed maintenance

- Poor capacity utilization

- Lack of visibility into production levels

Such issues can lead to delays, reduced product quality, and missed delivery deadlines—all of which can harm a company’s reputation. The Mendix tools available in the Manufacturing Menu help manufacturers tackle these challenges directly, ensuring they can use their resources efficiently and maximize their performance.

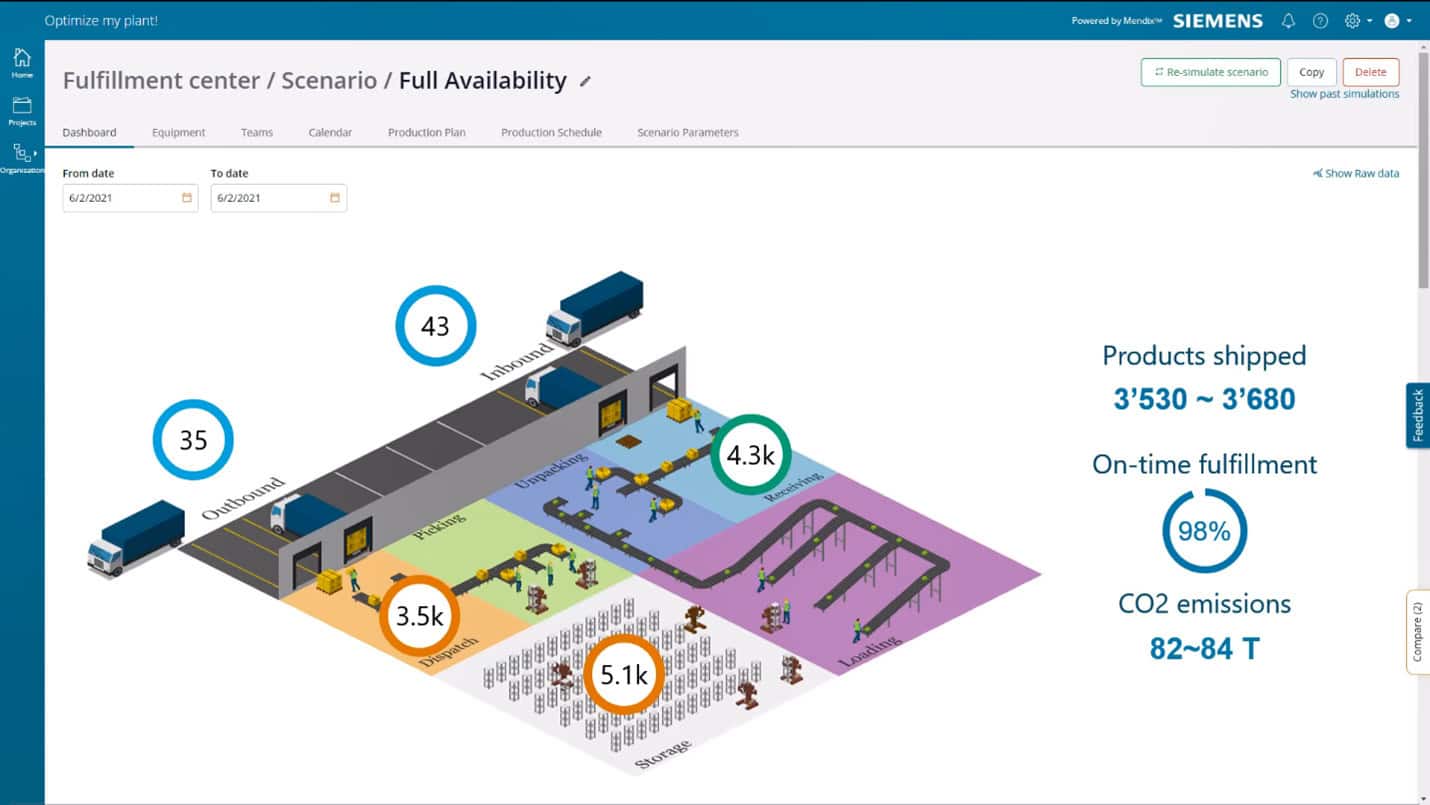

One such tool is the Optimize My Plant application, designed to help manufacturers improve utilization and performance across their operations. This application includes features such as:

- Predictive maintenance to prevent machine downtime

- Scenario planning to optimize delivery schedules

- Simulations that identify bottlenecks before they disrupt production

By providing real-time insights into all aspects of the production environment, Optimize My Plant enables manufacturers to make informed decisions that improve efficiency, reduce waste, and ensure timely delivery. This comprehensive approach to resource optimization allows manufacturers to respond quickly to unexpected challenges, maintain smooth operations, and consistently meet production goals.

Low-code for long-term success

As you can see, the Manufacturing Menu gives manufacturers the flexibility to not only improve current operations but to efficiently handle future changes and demands.

The Manufacturing Menu can provide this flexibility because Emixa built it with Mendix low-code. Mendix lets manufacturers create applications with pre-built, reusable components that they can quickly customize and scale to meet their needs.

Manufacturers can compose, customize, and reuse these components, making it easier to deliver solutions that keep up with the fast-changing business landscape. By integrating Mendix into your IT strategy, you can move beyond isolated ‘point solutions’ and create a flexible foundation that drives digital transformation and innovation across your enterprise.

To learn more about how the Manufacturing Menu can enhance your efficiency, safety, and resource use, positioning your organization for sustained success, visit the Emixa blog.

Bài viết cùng chủ đề:

-

Leave Request – Quản lý nghỉ phép thông minh trong một mô-đun CRM duy nhất

-

Techworld Solutions Đồng Hành Cùng UTE Trong Đào Tạo Nhân Lực Chất Lượng Cao

-

Microsoft Office chính thức chuyển thành Microsoft 365

-

Epicor Asia & Techworld Solutions Vietnam Chính Thức Công Bố Quan Hệ Đối Tác Chiến Lược, Mở Rộng Hệ Sinh Thái Giải Pháp Tại Việt Nam và Khu Vực

-

Chúc mừng đội ngũ Microsoft!

-

Giá trị của Microservices Doanh Nghiệp với Low-Code

-

Sự Tiến Hóa Tiếp Theo Của Mendix Cloud: Đón Nhận Kubernetes Để Xây Dựng Nền Tảng Sẵn Sàng Cho Tương Lai

-

Optimizing Production with Epicor ERP – Specialized Solutions for Complex Industries

-

Addressing the Knowledge Gap

-

AI-Assisted Development in Action with Mendix

-

Empowering Mobile Innovation

-

How to Upgrade Legacy Systems to Compete in the Cloud Age

-

TECHWORLD SOLUTIONS VIỆT NAM VÀ ĐẠI HỌC SPKT ĐÀ NẴNG KÝ KẾT HỢP TÁC TRIỂN KHAI TRUNG TÂM NGHIÊN CỨU & ĐÀO TẠO CÔNG NGHỆ SỐ

-

How to Architect Your Mobile Customer & Employee Experiences

-

PVI Gia Định Partners with Techworld Solutions Vietnam to Revolutionize Insurance Management

-

ESEC Group Partners with Techworld Solutions Vietnam to Implement Microsoft Dynamics 365 ERP